Static Process Equipment

- Heat Exchangers – With state-of-the-art machining resources, a skilled workforce and optimally streamlined operations, heat-exchangers have always been our core product.

- Reactors – Our collection of high pressure, high temperature and high metallurgy reactors are a great fit for oil and gas refineries, as well as the petrochemical, fertilizer and chemical industries across the globe.

- Pressure Vessels – We are very well equipped to supply a wide range of pressure vessels for varied operations in various units of oil & gas, petrochemical, fertilizers and chemical industries.

- Columns & Towers – We also offer various columns and towers for the energy sector. Our range of columns and towers includes packed columns as well as tray towers.

- Custom Fabrication – All this work is completed by metal fabricators — highly skilled specialists who are trained to cut and manipulate metal.

Technology Products

- Helix Changer – Helixchanger®, a shell & tube heat exchanger with helical baffles is a proprietary product of Lummus Technology. These highly efficient exchangers offer major benefits such as lower pressure drop, reduced vibrations, higher heat transfer co-efficient and lower footprint over conventional shell & tube heat exchangers.

- EMBaffle Heat Exchanger – An Advanced Technology in S&T Heat Exchangers especially for gas applications. Patented Technology Owned by Brembana & Rolle, Italy. Originally developed by Shell to address fouling issues in crude pre-heater. Allows handling of operational issues (vibrations, corrosion, fouling)

Dished Ends

With top-of-the-line machining resources and a skilled workforce, heat-exchangers have always been our forte. We offer a complete range of Shell & Tube Heat exchangers for oil & gas, refinery, petrochemical, fertilizer, power, water & waste water and chemical industries.

Our range of heat exchangers includes evaporators, high-pressure feed water heaters, surface condensers, waste heat exchangers, multi-tube hairpin exchangers, bayonet heat exchangers, catalyst coolers, transfer line exchangers, RG boilers etc.

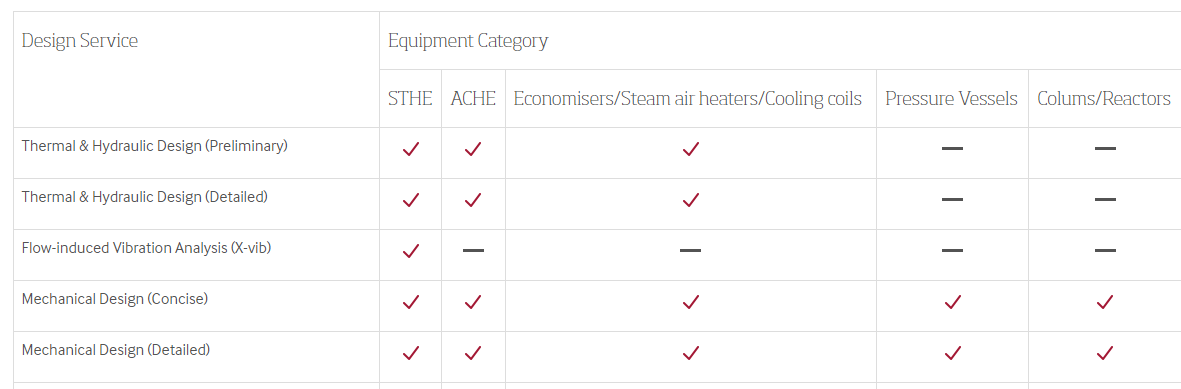

Engineering Services

- HTRI with Xist and X Vib Version 8 SP3 for thermal design of heat exchangers ANSYS19 and NozzlePRO for FEA and Fatigue analysis

- PVElite 2020 and Microprotol for mechanical design

- PDS (inventor) for 3D modelling

Industrial Centrifuges